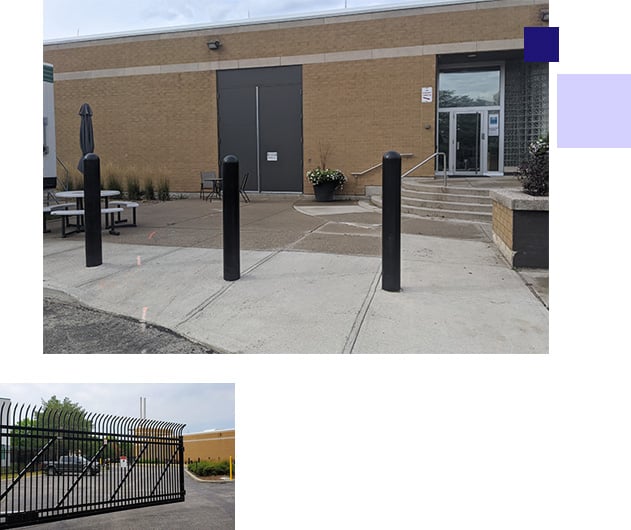

Conference Rooms

Large screen TV and comference equipment is availble. Seating for up to 12 People. Available for anyone to use.

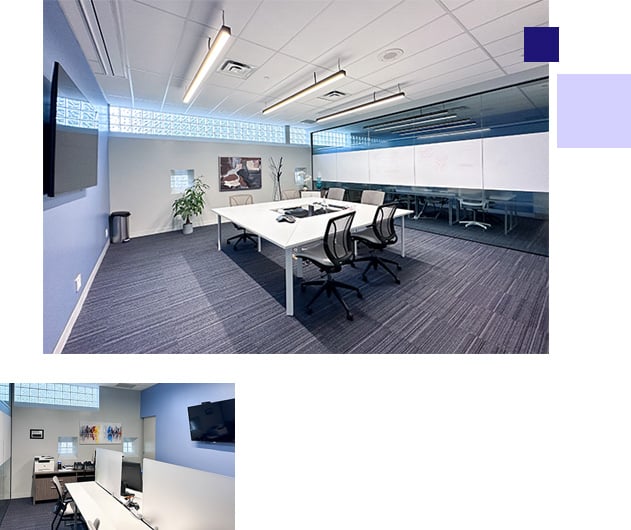

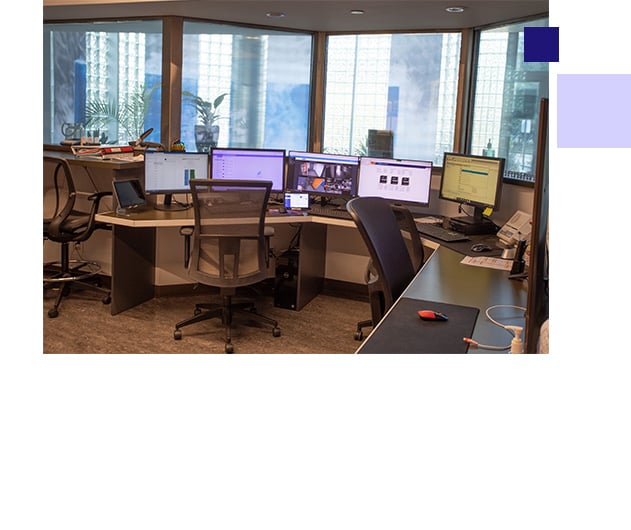

Tenant Office Space

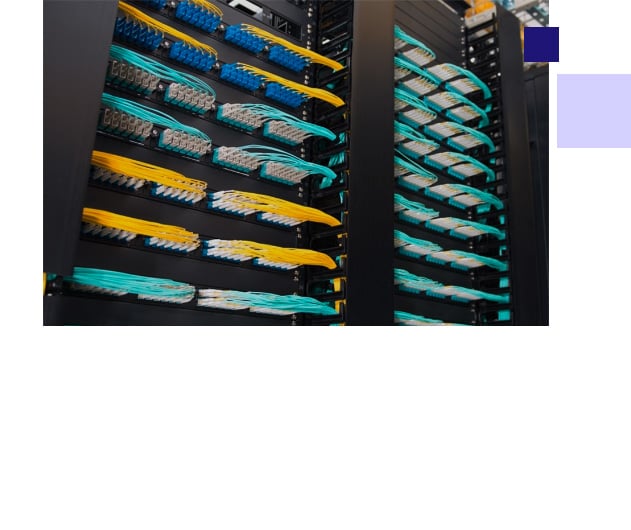

Desks and chairs are available in the Tenant office Spaces. Desk phones along with data drops for internet access. Wi-Fi access is also available.

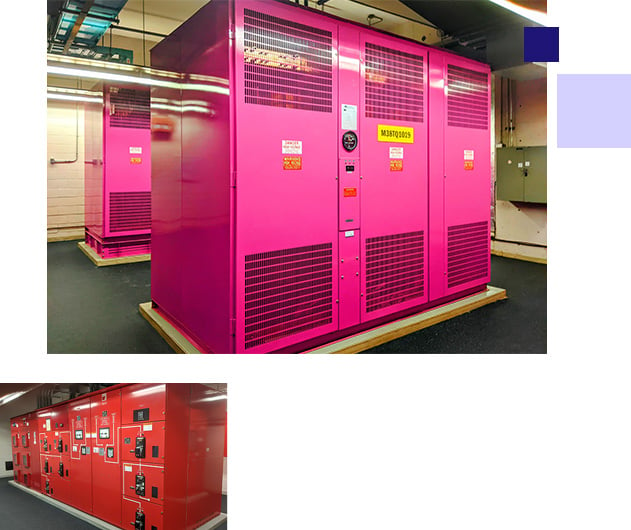

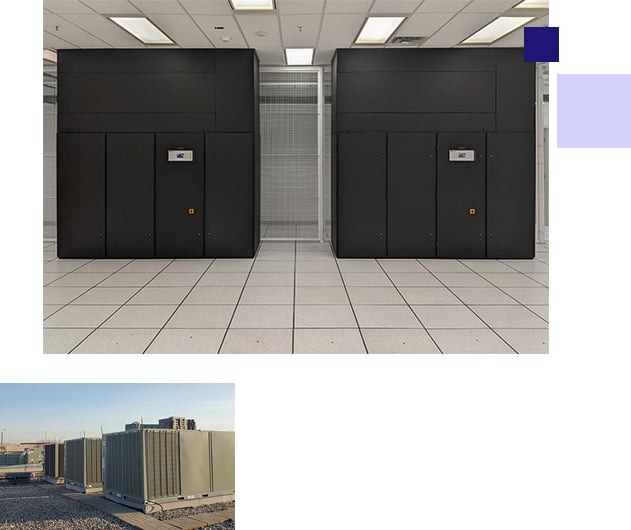

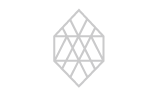

The purpose-built Data Center facility provides a multi-layered security environment.